A collaborative research and development project between the Estonian Academy of Arts and partners showed where textile waste is going in Estonia and what can be done with it.

The 1.5-year project "Developing solutions for recycling and product innovation of textile waste generated in Estonia", led by the Estonian Academy of Arts DiMa and supported by the Environmental Investment Centre, has been completed and a report summarising the results of the project has been published (READ HERE). The aim was to develop recycling solutions for textile waste generated in Estonia as a basis for further development of the textile recycling system.

Consumption of textile products has grown exponentially over the last two decades. At the same time, the vast majority of used clothing and textiles end up as waste, either in landfills or incinerated. In the European Union, for example, around 5.8 million tonnes of textile products are landfilled, or about 11 kg per person per year. Studies show that 19 300 tonnes of waste clothing and textiles were generated in Estonia in 2020. Given the current lack of recycling facilities for this waste group in Estonia, the vast majority of it is landfilled, where it is an environmentally harmful and extremely slow composting residue.

In order to develop the recycling of textile waste generated in Estonia and to find solutions, DiMa conducted this research project in cooperation with SEI Tallinn, the Polymers and Textile Technology Laboratory of TalTech and the Wool Laboratory of Viljandi Culture Academy.

The research project was divided into four phases:

1) Study on textile waste generated in Estonia.

In the first phase of the project, SEI Tallinn carried out a survey using an analytical methodology to classify different categories of textile waste and estimate their volumes. This allowed to identify the quantities, categories and technologies of textile waste that can be implemented with minimum investment to ensure a primary pre-processing capacity for used clothing and textiles in Estonia. The results of the study showed that, from a technological and economic point of view, 3 300 tonnes of the clothing waste generated in Estonia per year could be mechanically treated quite easily and used as secondary raw material for the production of new products.

2) Collecting, cleaning and praising textiles.

In order to find recycling solutions, 425 kg of old clothes (T-shirts, jeans, home textiles) were collected with the help of the MTÜ Uuskasutuskeskus. These were mechanically shredded by Paragon Sleep, a company with a re-drying line designed to shred post-production textiles. The activities carried out clearly showed that there is a lack of solutions and technology for separate collection and pre-treatment of textile waste in Estonia today.

VIDEO - sorting and cleaning of textile waste.

VIDEO - shredding and polishing textile waste.

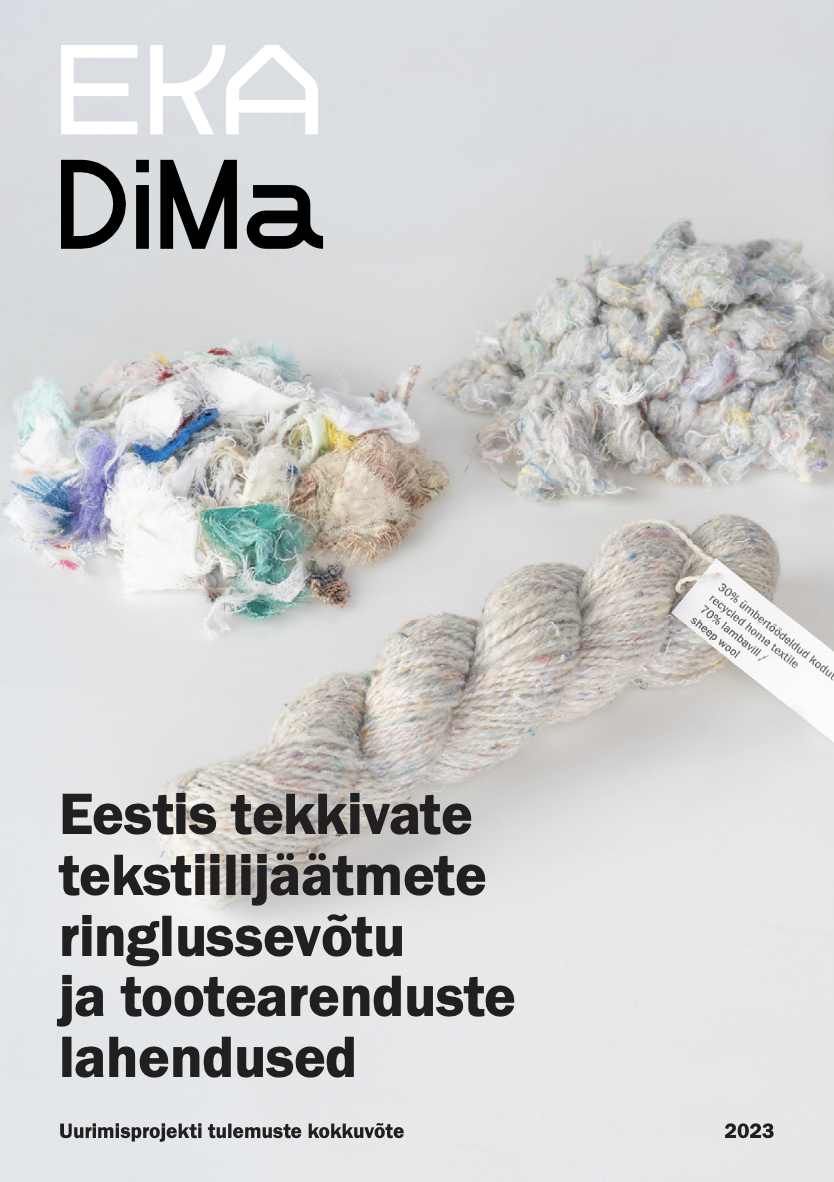

3) Developing new materials from crushed fibre.

Material development to obtain nonwovens from crushed fibre pulp was carried out in the Polymers and Textile Technology Laboratory at TalTech. As a result, nonwovens with different compositions, structures and stiffness were produced. The second direction of material development was yarn development, which was carried out in the Vilma wool laboratory of Viljandi Culture Academy and resulted in yarns with four different compositions.

VIDEO - development of nonwovens made from crushed fibre.

VIDEO - development of yarns from broken fibre pulp.

4) Product development from new materials.

The product development process was carried out at the EKA. From the finished nonwovens, hot-pressed composite boards were selected for further processing, from which small furniture samples were made (designer Argo Tamm). The yarn development resulted in the development of hand knitted fabrics (designer Maria Kristiin Peterson) and seamless knit headwear (designer Reet Aus).

VIDEO - product development from new materials.

Project funded by the EParticipants: senior researcher Reet Aus, researcher Kärt Ojavee, project manager and designer Maria Kristiin Peterson, designer Argo Tamm.nvironmental Investment Centre, Circular Economy Programme.

Participants: senior researcher Reet Aus, researcher Kärt Ojavee, project manager and designer Maria Kristiin Peterson, designer Argo Tamm.

Partners: SEI Tallinn, Viljandi Academy of Culture, TalTech Polymers and Textiles Laboratory, Uuskasutuskeskus, AS Paragon Sleep.

See more photos from the DiMa exhibition gallery at the XVII Design Night. HERE.

READ THE REPORT HERE.