Development of recycling and product development solutions for textile waste generated in Estonia

Today, there is a lack of textile waste recycling capacity and technology in Estonia. The annual consumption of new clothing and household textiles in Estonia is around 16 000 tonnes. Today, nearly half of the separately collected clothing and textiles in Estonia (totalling nearly 2,500 tonnes/year) is diverted to landfill. In addition to separately collected clothing and textiles, a large proportion of used clothing is thrown away in mixed municipal waste (around 15 000 tonnes/year). From there, it is already sent for treatment together with mixed municipal waste, which in Estonia is either mass incineration in an incineration plant or landfilling. At the same time, under the EU Waste Directive, all Member States will be obliged from 2025 to separately collect all textile waste generated.

The aim of the completed project was to find recycling solutions for this separately collected clothing and textile waste. A summary of the results of the completed project in Estonian can be found in the report below:

Authors of the report: Harri Moora (SEI Tallinn), Maria Kristiin Peterson (DiMa), Reet Aus (DiMa), Kärt Ojavee (DiMa), Astri Kaljus (Viljandi Kultuuriakadeemia), Tiia Plamus (TalTech).

See more photos from the DiMa exhibition gallery at the XVII Design Night HERE.

The following activities were carried out within

the project:

1. Textile waste analysis, the aim of which was to map the most promising types of textile waste generated in Estonia, which are the easiest to recycle and use in material and product development. The study was carried out by SEI Tallinn.

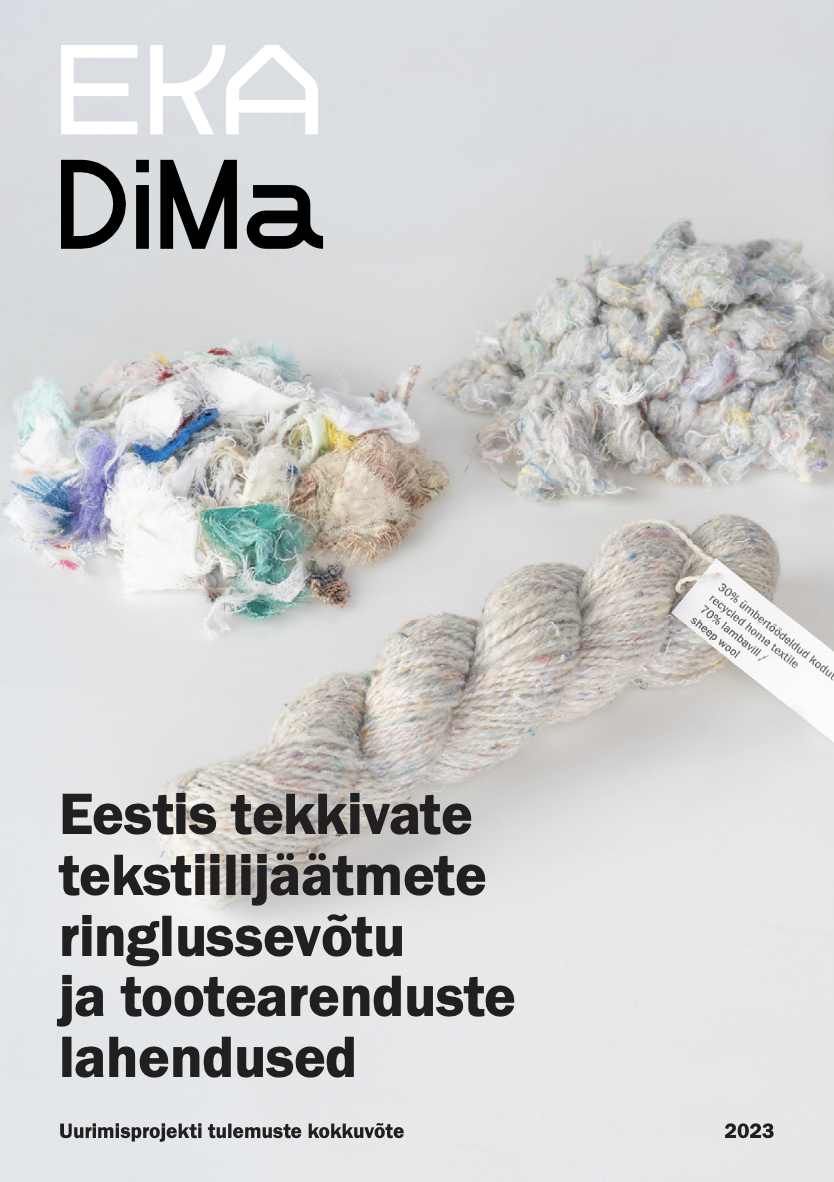

2. Collection, cleaning of textiles. In cooperation with MTÜ Uuskasutuskeskus, 425 kg of old clothes were collected for the project. These were mechanically shredded and pulled apart into fibers on the Paragon Sleep defibering unit.

Sorting and cleaning of textile waste

Shredding and fiberizing of textile waste

3. Developing new materials from crushed fibre. Material development for nonwovens from crushed fibre pulp was carried out in the Polymers and Textile Technology Laboratory at TalTech. As a result, nonwovens with different compositions, structures and stiffness were produced. The second direction of material development was yarn development, which was carried out in the Vilma wool laboratory of Viljandi Culture Academy and resulted in yarns with four different compositions.